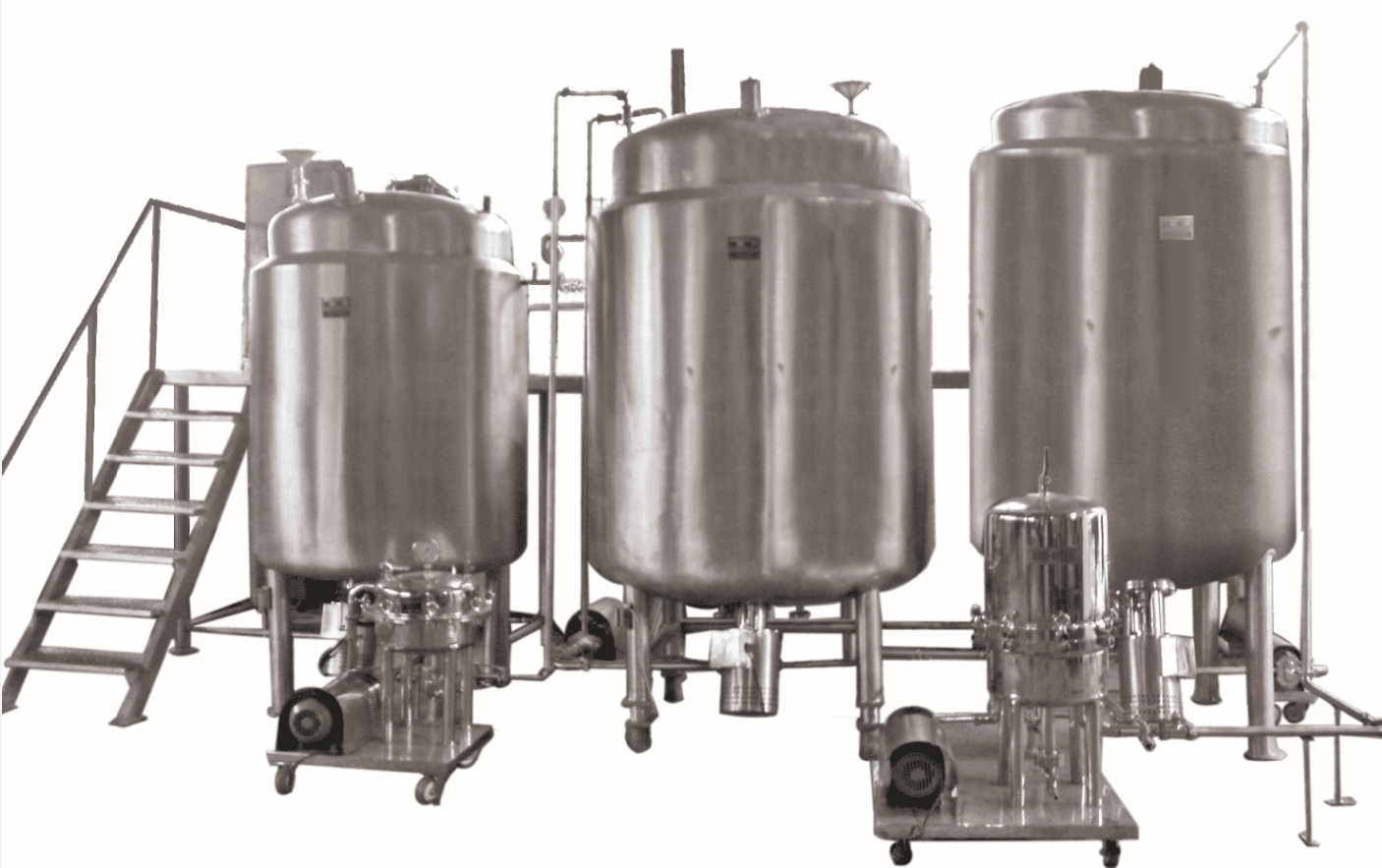

LIQUID SYRUP MANUFACTURING PLANT

The liquid syrup manufacturing plant also known as liquid oral manufacturing plant is suitable for the preparation of pharmaceutical syrups, liquid orals, suspensions, and many more.

Equipment Design

- Sugar or primary syrup manufacturing vessel

- Sugar or primary syrup manufacturing vessel

- Sugar filtration system

- Main manufacturing vessel

- Final filtration system

- Inline homogenizer

- Final product storage vessel

- Sanitary Inter-connecting piping

- Central control panel

- Integrated working platform for easy access

Salient Features

- The Ravi Kiran make Liquid Syrup smanufacturing plant is designed as per the cGMP and FDA guidelines.

- The Ravi Kiran Liquid Syrup manufacturing Plant is provided with individual level of process control at each level of manufacturing process.

- The completely integrated system with interconnection makes it easy for the operation, cleaning and validation of the plant.

- CIP facility for all vessels as per CGMP requirements

- The sugar syrup preparation vessel is provided with a double jacket with mineral wool insulation for the heating operation for sugar syrup preparation. The final manufacturing vessel is provided with a full jacket for heating and / or cooling operations. The jacket is also provided with a mineral wool insulation with S.S. cladding as per GMP specifications.

- The primary vessel, the main manufacturing vessel and the final storage vessel are provided as a standard with bottom entry high speed stirrer mounted on the bottom dish with standard mechanical seal of SIC Vs SIC face combination for trouble free operation. The mechanical seals are with jacket with cooling arrangement as a standard.

- The speed of the mechanical stirrers for the vessels can be set from the Variable frequency drive provided in the panel as per the manufacturing process requirement and as mandated in the standard operation procedure (SOP) for the product manufacture.

- The vessel is provided with internal baffles which are removable type for easy cleaning and gentle mixing. The baffles also help prevent vortex for better mixing.

- An In-line homogenizer is provided for the manufacturing vessel for the preparation of the suspensions, emulsions, and similar difficult to mix products.

- All the gaskets provided in the plant are of Food Grade Silicon Gaskets with validation certificates.

- The Ravi Kiran make Plant is provided with a pre filter for the sugar syrup filtration and a final filter for the filtration of the final liquid after manufacturing in the main preparation vessel.

- The plant piping is provided with sanitary tri-clover fittings for complete dismantling and opening of the line for cleaning and passivation during product changeover.

- CIP facility for all vessels

- The interconnection pipe line is provided with sampling points at suitable locations. It is also provided with cleaning and validation points.

- The liquid syrup plant is provided with a single control panel located at a suitable location on the platform to operate and control all the processes from a single location.

- A Full S.S. working platform with dimpled floor, stair case and railing is provided for the length of the plant with suitable arcs as per the vessel diameter for easy access and operation of the vessels.

- An optional Vacuum loading system with vacuum pump for direct loading of sugar into the primary sugar preparation vessel can be provided.

- Dynamic load cell with independent control unit can be provided for the primary sugar preparation and the main manufacturing vessel.

- The control panel can be provided with a PLC based panel with MIMIC and menu options for complete automation and data validation.

APPLICATION

- Pharmaceutical formulations

- Suspensions

- Cough syrups

- Nutraceuticals

EQUIPMENT STANDARDS & CERTIFICATION

- cGMP, FDA, ASME, WHO, ISPE, BPE, ANSI, 21CFR, UKCA, CE , 21 CFR and SCADA compliant